Inspecting pipelines with tight bends and confined spaces has traditionally been a challenging task for plumbing and maintenance professionals. Standard inspection methods often require excavation or manual probing, which is time-consuming, costly, and sometimes damaging to the infrastructure. Sewer cameras provide a modern, non-invasive solution, allowing operators to examine even the most complex pipeline networks with precision and efficiency.

Table of Contents

ToggleDesign Features for Maneuverability

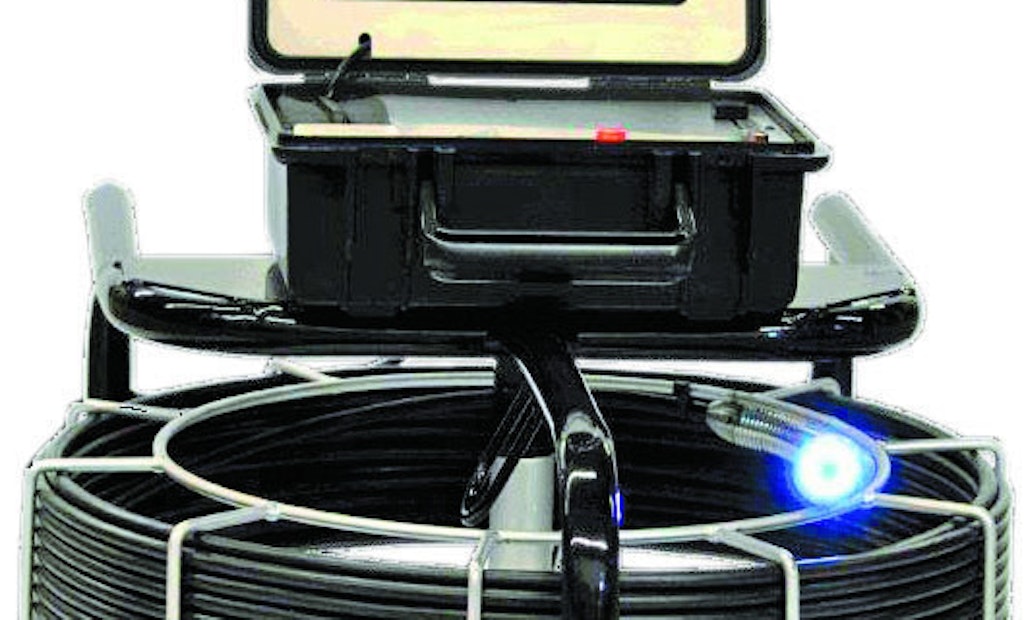

Sewer cameras are specifically engineered to navigate tight and curved pipelines with minimal effort. Advanced systems like the Sewer Camera incorporate flexible push rods, compact camera heads, and articulated designs to move smoothly through bends and narrow sections. The combination of lightweight construction and high durability ensures that cameras can traverse obstacles, bends, and diameter changes without causing damage to the equipment or the pipeline itself.

Flexible Push Rods and Cable Systems

A critical component enabling sewer cameras to navigate challenging pipelines is the flexible push rod or cable system. These rods are designed to bend gradually without kinking, allowing the camera to move around sharp corners and vertical drops. Multi-layered, reinforced construction provides both flexibility and durability, ensuring consistent performance even in older or corroded pipes. Flexible push rods reduce the risk of getting stuck, which is especially important in residential and commercial plumbing networks.

Compact Camera Heads

The size and shape of the camera head are essential factors for maneuverability. Smaller, compact camera heads can easily pass through narrow pipes, bends, and junctions. Many systems include rounded or beveled edges to minimize friction and prevent snagging on pipe walls or debris. Some cameras are designed with detachable heads, allowing operators to select the appropriate size for specific inspection scenarios, improving both access and operational efficiency.

Pan-and-Tilt Functionality

Pan-and-tilt mechanisms greatly enhance the camera’s ability to inspect curved and angled sections of pipes. Operators can rotate and angle the camera head remotely, ensuring that every portion of the pipeline is visible without manually repositioning the entire system. This feature is particularly useful in pipelines with multiple bends or T-junctions, allowing for comprehensive inspection while minimizing time and effort.

Real-Time Navigation and Visual Feedback

Effective navigation of tight pipelines relies on continuous visual feedback. High-resolution monitors provide real-time images, allowing operators to steer the camera precisely through curves and around obstacles. LED lighting integrated into the camera head illuminates even the darkest sections of the pipeline, ensuring that structural defects, blockages, or corrosion can be detected during navigation. The combination of real-time feedback and precise control significantly improves inspection accuracy.

Durability and Environmental Resistance

Navigating tight and curved pipelines exposes sewer cameras to friction, moisture, and debris. To maintain functionality, camera systems are constructed from durable materials resistant to corrosion, impact, and water ingress. Reinforced housings, waterproof seals, and protective coatings safeguard both the electronics and optical components, ensuring that cameras can operate reliably in challenging underground environments.

Operator Ergonomics and Control

Ease of operation is another key factor in navigating complex pipelines. Modern sewer cameras are designed with intuitive controls, allowing operators to adjust speed, camera orientation, and lighting without interrupting the inspection. Ergonomic hand controls or touch interfaces reduce operator fatigue during extended inspections, enabling precise maneuvering through tight spaces.

Applications in Residential and Commercial Systems

Sewer cameras’ ability to navigate tight and curved pipelines makes them ideal for a wide range of applications. In residential settings, they can inspect older homes with narrow or angled pipes, detect clogs, and assess pipe integrity without excavation. In commercial or industrial systems, cameras provide access to intricate networks, vertical drops, and junctions that are otherwise difficult to inspect. This versatility ensures that all areas of a pipeline can be monitored efficiently and effectively.

Conclusion: Precision Navigation for Comprehensive Inspections

Sewer cameras have transformed pipeline inspection by enabling precise navigation through tight and curved pipelines. Features such as flexible push rods, compact camera heads, pan-and-tilt mechanisms, and real-time visual feedback allow operators to examine even the most complex networks without excavation or disruption. By combining durability, maneuverability, and operator-friendly design, sewer cameras ensure accurate, efficient, and safe inspections, making them indispensable tools in modern residential, commercial, and industrial plumbing management.